LTW – Engineers of Flow

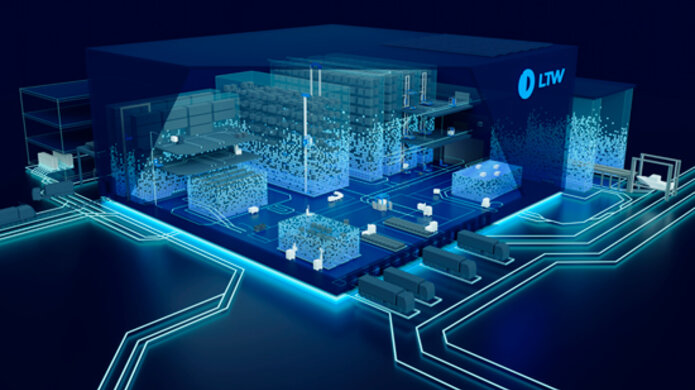

At LTW Intralogistics, we are engineers of flow – standing still is not in our vocabulary. For over 40 years, our name has been synonymous with top-tier quality and precision. With more than 950 successful projects completed across 35+ countries, we’ve demonstrated consistent productivity. Always on time, always precise.

Our turnkey solutions offer maximum system availability, optimal space utilization, and secure storage for a wide range of products. Flexibility is one of our key strengths. While most components are manufactured by our parent company, Doppelmayr Holding SE, we focus entirely on meeting our customers' needs. Built to ropeway standards, our production quality ensures robust and durable intralogistics systems for clients worldwide.

LTW and Doppelmayr – the perfect match. As part of the Doppelmayr Group, we benefit from advantages that directly benefit you. One of our key quality features is production according to ropeway standards, ensuring exceptional reliability. Did you know we’re part of the Doppelmayr Group? This global leader in ropeway construction expanded into intralogistics in 1981 to balance seasonal production fluctuations. Today, we are a core pillar of the Doppelmayr Group, continuing to deliver innovative solutions backed by decades of expertise.

- Headquarters

- established

- Locations

- Countries

- projects

- . .storage spaces

- /there for you

Related topics

Below you will find other products and services from the LTW world that may be of interest to you.