Stacker cranes

Guaranteed quality with full flexibility

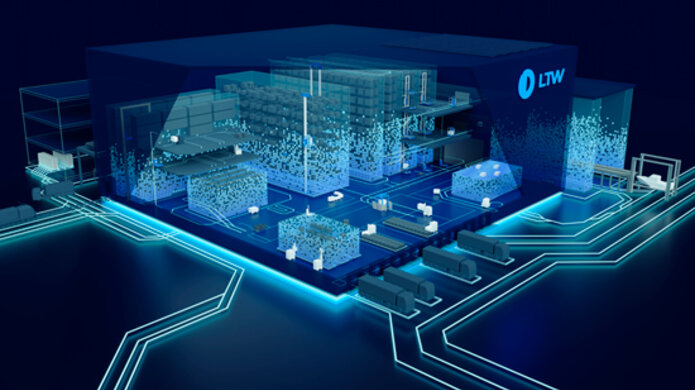

With over 40 years of experience, we have built more than 2,500 rail-mounted stacker cranes, accumulating extensive expertise across various sectors. One of our key quality features is our production standard, which adheres to ropeway specifications, thanks to our affiliation with the Doppelmayr Group. As the global market leader in ropeway construction, Doppelmayr manufactures nearly all of our moving parts, allowing us to focus entirely on system layout design—unleashing our creativity without limits.

Whether you need stacker cranes for 31-meter-long stored goods, containers weighing up to 18,000 kg, or boats, we provide solutions that span from standard pallet warehouses to large-scale heavy-duty systems. This versatility allows our stacker cranes to be used across a wide range of sectors, including food production, deep-freeze storage, automotive, and the highly sensitive pharmaceutical industry. We are dedicated to meeting our customers' individual requirements effectively.

Innovation Takes Many Forms

All of our stacker cranes are constructed to ropeway standards and are available in various configurations. We offer single, double, or four-mast options, as well as aisle-bound or aisle-changing stacker cranes, depending on your requirements. Our commitment to continuous product development ensures we stay aligned with the latest trends in the industry.

Our components feature proven control technology in a modular design, ensuring robust performance and dirt resistance. This design, combined with straightforward expansion options and long product life cycles, guarantees smooth operation. Furthermore, cameras can be installed on the lifting carriages of our stacker cranes at the request of our customers, facilitating easy troubleshooting even at significant heights. Our digital service platform, LTWcare, offers a live view of image data at any time, further enhancing operational efficiency.

Switch Technology

Did you know that our in-house developed aisle-changing mechanism eliminates the need for transfer devices, monitoring equipment, or extensive maintenance? Additionally, a limited number of stacker cranes can effectively cover large areas of the warehouse, making it a cost-effective solution where handling capacity isn't the primary concern. The most significant advantage of our switch technology is its ability to provide redundancy in system operation by utilizing multiple stacker cranes. What does this mean for you? It ensures the highest possible availability of your goods in the warehouse, maximizing efficiency and reliability.

Heavy-duty

Over the decades, we have successfully executed a diverse range of projects in the heavy-duty sector. A significant milestone was the construction of a stacker crane capable of handling goods measuring 31 meters in length and weighing 13.5 metric tons. We built the first stacker crane equipped with a push/pull device for such large items on behalf of an Austrian materials manufacturer. This crane consists of two RBG frames and features a three-part lifting carriage with a total width of approximately 31 meters. The overall weight of the stacker crane, including its payload, reaches an impressive 80 metric tons! Our heavy-duty solutions find applications across various sectors, including material manufacturing, wood processing, and mechanical engineering.

Shuttle System

When speed is essential, we offer an innovative solution: a shuttle system that employs multiple stacker cranes positioned vertically in an aisle. The seamless coordination between the vertical conveyor and the stacker cranes is crucial, as transport units are moved to and from the respective stacker cranes, which primarily operate in a sideways motion. This design maximizes the speed and efficiency of the stacker cranes, delivering high-performance results for your operations.

Hybrid Stacker Crane

Our stacker cranes can now be equipped with energy storage units (supercaps). What does this mean? Simply put, these energy storage units, combined with intelligent load management, ensure that energy is never wasted; instead, it is fully reused. This innovation can save up to one-third of the energy typically consumed. Another key advantage is that the required connected load is reduced by 80% thanks to the supercaps, which allows for a significantly smaller diameter power supply cable for the stacker crane. As a result, our hybrid stacker crane promotes energy conservation and efficiency in your operations.

Order Picking Doors

Our patented picking door system provides a safe and seamless solution for order picking within the high-bay warehouse, located directly alongside the stacker crane lane. How does it work? The doors slide horizontally to maintain a separation between the stacker crane lane and the picking area, only opening when goods are moved from the storage area to the picking area. This design requires only one drive per picking area and side on the stacker crane, resulting in cost savings and reduced complexity in cabling.

Related Topics

Below you will find other products and services from the LTW world that may be of interest to you.