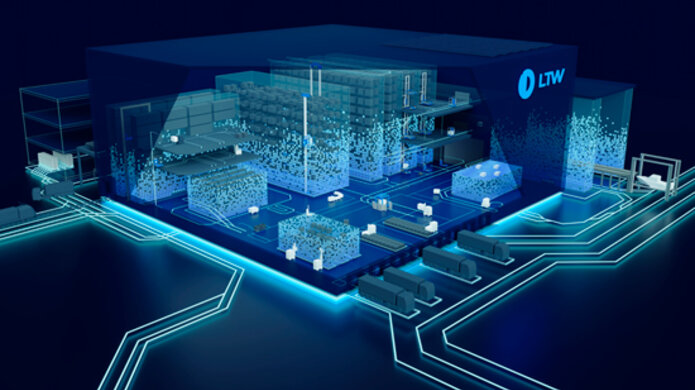

High-bay warehouse

Large or small, heavy or light—we can store nearly anything for you, whether your goods are in containers, on pallets, or on special load carriers. With a robust manufacturing facility at our disposal, we can identify the optimal solution for your needs. The key is to select the best storage strategy to maximize efficiency. We consider various storage approaches, such as FIFO (First In, First Out) or FEFO (First Expired, First Out), and can also assist you with inventory management and stocktaking.

Related topics

Below you will find other products and services from the LTW world that may be of interest to you.